Phosphating processes

Phosphating processes:

According to heading fall such processes as result in formation of an insoluble phosphate coating on the surface of a metal. The formation of such coatings is invariably linked with the corrosion of the substrate metal. In a narrower definition, phosphating processes are only those which form surface coatings with useful properties. Thus phosphoric acid pickling solutions are a marginal case, since their primary function is removal of corrosion products and their usefulness in forming protective phosphate coating is very much a secon dary one.

Technically and economically, the most important processes are those based on aqueous solutions which form protective coatings on metal surfaces, whether by spraying, pouring, immersion or other methods. Depending as to whether or not components are coated on removal from the solution, one may distinguish between the so-called phosphate coating processes and the 'non-coating" alternatives. In addition, there are phosphating processes based on non-aqueous media, but these have no practical significance at this time. Finally, there are processes based on the reaction of the metal surface with the adherent, residual film of phosphoric acid after removal from solution and following heating. These are used only in very restricted applications.

Phosphate coating process:

Phosphate coating processes utilise dilute aqueous which, in contrast to the non-coating processes, contain all the main constituents required for coating formation i.e. the phosphate anions and at least some of the metal cation. During the phospiting processes the metal is in contact with a large volume of the phospiting solution, allowing ready exchange between species in the near surface liquid layer and the bulk of solution. The extent of such exchange depends on the type of process being used.

1. Degreasing:

Removal of Greece and oil alkaline conditions ( hydroxides, surfactant, emulsifiers)

2. Rinsing:

Rinsing with water.

3. Pickling:

Remove the inorganic residue (rust) acids ( hydrochloric acid, phosphoric acid, sulphuric acid)

4. Rinsing:

Rinsing with water.

5. Activation:

Creation of nucleation on the top of layer of metal (titanium salt). This step determine the character much later phosphate layer.

6. Phosphating:

Zinc formation of the phosphate layer with phosphoric acid, and zinc salts.

7. Rinsing:

Rinsing with water.

8. Passivation:

Protection for the addition of salts (such as chromium salts).

Uses of phospiting:

The main uses of phosphating are:

- Corrosion protection in conjunction with organic coatings, such as paints and polymer film.

- Facilitation of cold forming processes, such as wire drawing and tube drawing or deep drawing.

- Corrosion protection in conjunction with oil and waxes.

- Corrosion protection with no subsequent treatment.

- Improving anti-friction properties, such as break-in, wear resistance, anti-galling and reducing the coefficient of friction.

- Providing a strong adhesion bonding for subsequent painting or an organic coating.

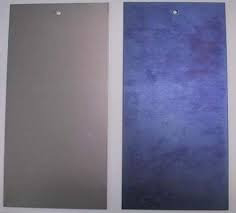

The main types of phosphate coatings are manganese, iron, and zinc

- Manganese phosphate coatings are used both for corrosion resistance and lubricity and are applied only by immersion.

Source: Internet

- Iron phosphate coatings are typically used as a base for further coatings or painting and are applied by immersion or by spraying.

- Zinc phosphate coatings are used for corrosion resistance, as a lubricant-holding layer, and as a paint/coating base and can also be applied by immersion or spraying. They can also be applied to galvanized steel.

Source: Internet

Comments

Post a Comment